In March when COVID-19 brought the U.S. to a stand-still, Michelle reached out to TCG (through PM Response) about helping the Brain Injury Association of New York State (BIANYS) virtualize their conferences and walks. Our team quickly went to work identifying a project manager and devising the best plan for BIANYS to tackle this new challenge.

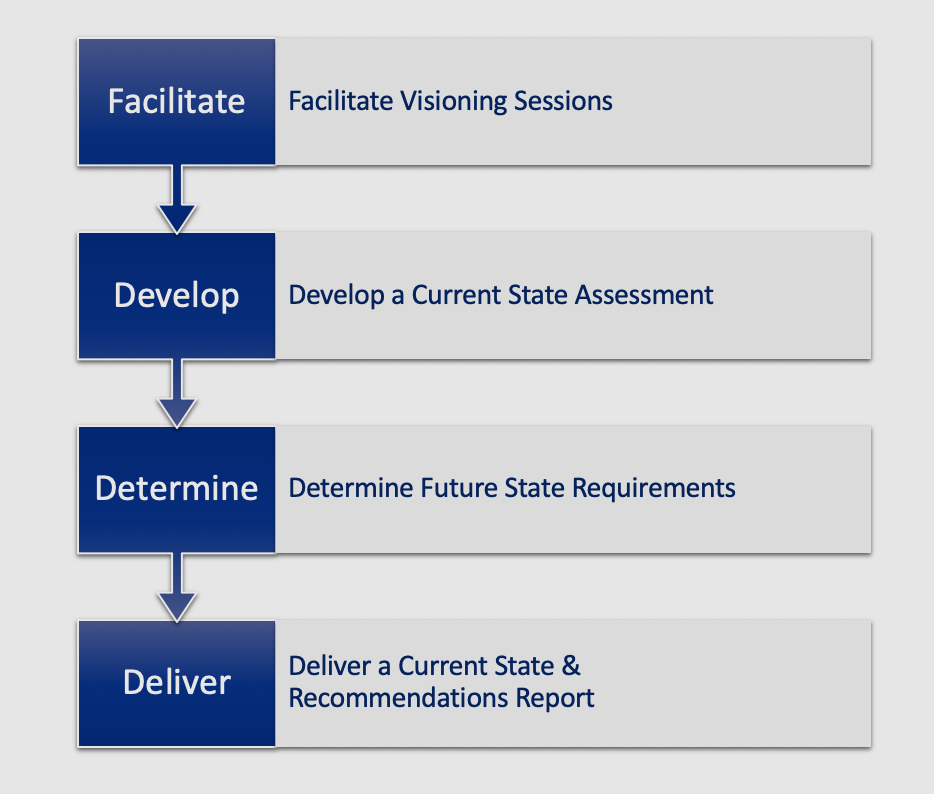

Hannah Fisher stepped into the PM role and helped lead the initiative to virtualize the March On for Brain Injury, BIANYS’ annual walk series. We used our standard approach for simple IT source selections.

Our team worked with BIANYS to come up with these four high-level themes for the walk:

- Leverage existing core technologies for 2020 events

- Reimagine the marketing strategy and social media presence

- Demonstrate the quantity and volume of impressions to the sponsors

- Develop a live experience with pre-recorded content

We developed 35 recommendations which were broken down into five categories:

The 2020 version of the walk will feature a custom-built landing page that will present all of the content for the event. Participants will get the simulated experience of an in-person walk, and inspiring speeches will be delivered via pre-recorded and live video throughout the day.

If you’re interested in supporting a great cause, please head over to their website and sign up for the walk or make a donation.

This is the first of a two-part series that features the IT source selection approaches we took with BIANYS. The next part will include an overview of our more complex source selection process which involves developing an RFP and facilitating demos with potential vendors. Be sure to subscribe to our blog updates if you don’t already do so.