Summary: My name is Andrew Guidarelli, and I am Tuck’s Strategy and Partnerships Manager. I started working for Tuck as a contractor in 2019 and joined the team as a full-time employee in March 2021. Since then, I’ve had the opportunity to work on both the client-facing and the operations side of the business, which gives me a unique perspective on the value that we bring to an engagement. Specifically, I’ve watched our consultants employ tools like ClickUp to address a wide range of business problems. This post is about how I leaned on institutional knowledge and best practices to make dramatic enhancements to an internal processes.

The Challenge

One of the most time-consuming and repetitive aspects of my job is drafting and delivering NDAs, teaming agreements, and contracts. That’s why automating that process (among others that affect invoicing and sales) became a goal of mine for Q3.

Defining a Solution with OKRs?

I’ve been a Tuck employee since March 2021, so I’ve seen the organization go through 10 quarters of growth and adaptation. My arrival coincided with Tuck implementing a goal-setting methodology called Objectives and Key Results, or “OKRs.”

A quick summary of how we use OKRs: Before the start of a new quarter, the leadership team develops a list of our biggest pain points and market opportunities. We establish priorities by voting on those changes, and top 5 to 7 become the Objectives. Finally, we identify 3-5 quantifiable benchmarks that, if achieved, would effect the desired change: our Key Results (“KRs”).

Applying Project Management Tools and Techniques

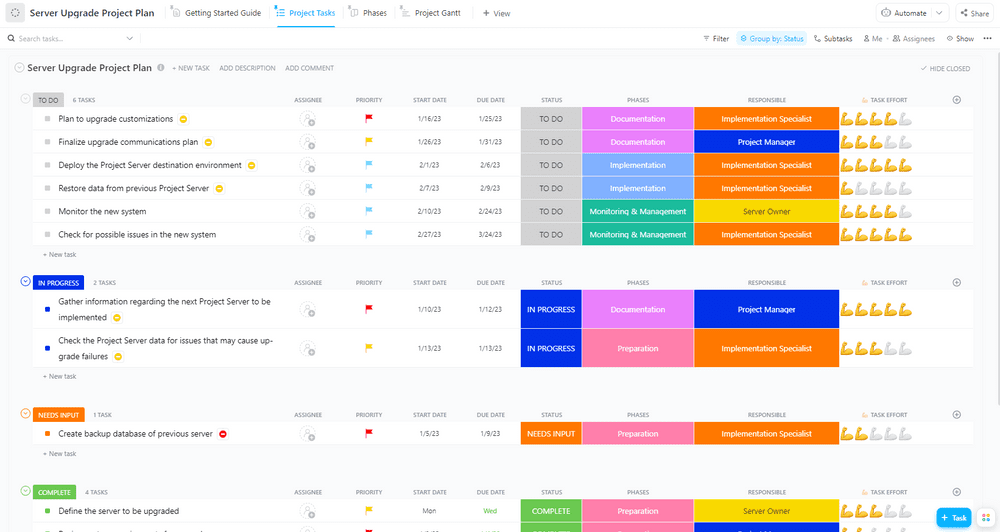

A bit of the solution was already sketched out when the KR was published, and to be honest, I was eager to start building it and refining it through trial and error. But that’s not the Tuck way. Because our consultants face similar requirements from clients regularly, I was coached into creating a ClickUp List with a simple project plan for drafting, developing, testing, and finally implementing a solution for my documentation woes.

Since I am far more of a consumer of project management services than a PM, and because I was concurrently migrating our CRM from Microsoft Dynamics to HubSpot (a far superior platform for SMBs, especially in its OOTB configuration), I was reluctant to apply a formal project plan to what I perceived to be a linear task. In fact, I thought that it could be accomplished within hours: we’d buy licenses for document automation software (we chose PandaDoc), then write some additional fields into HubSpot and connect the platforms with an API (HubSpot has a ton of native ones).

As it turned out, fully automating this contract-writing process was far more complex than I imagined. Through several brief user interviews, I realized that I had not accounted for other requirements like:

- Fully-executed contracts require Tasks to be within other Folders and Lists in ClickUp; the status quo asks reminders built into our ClickUp project planning tool

- Existing document-naming conventions and aesthetic details could not accommodate outputs from certain HubSpot fields, meaning we had to standardize and simplify them

- Most of the consultants currently on projects had onboarded prior to Q3, so we had to motivate them to repopulate their HubSpot profiles with new information (we built a new HubSpot form to collect this data).

After several false starts, I finished the rudimentary project plan in ClickUp. It was a simple one (more Waterfall than Agile), but building out a project plan allowed me to prioritize tasks, delegate the development work beyond my capabilities, and address each issue in turn. For the requirements mentioned above, I:

- built a new ClickUp automation created onboarding tasks for new consultants or consultants

- streamlined the format of contractual agreements so that auto-populated fields became indistinguishable

- approached consultants within the Tuck network systematically to fill out a revised capability survey (they stepped up with overwhelming participation)

In the end, our new process for creating, executing, and archiving contracts was online before the new quarter began, putting us ahead of schedule!

Conclusion

While it’s a no-brainer to apply project management principles to complex, wide-ranging, and expensive initiatives (you can read about some that we’ve undertaken here, applying them to more modest ones within your own organization can meet resistance. As I wrote earlier, I was reluctant to invest the time in adopting a formal project plan to achieve one of my KRs. Thanks to the simplicity and convenience of ClickUp, and to the project templates that my colleagues already built, I was able to overcome that resistance pretty quickly, and to achieve an objective that had been at risk a month earlier.

I was able to accomplish my goal so quickly because I had access to the same tools and expertise that Tuck clients do. I also had the flexibility of moving my project deadline backwards because it wasn’t mission critical. In many cases, getting your project completed within a given time frame is mission-critical. For those situations, our team of expert project management professionals can help – let’s talk more.

Andrew Guidarelli

Strategy & Partnerships

As Tuck’s Strategy and Partnerships manager, Andrew builds and nurtures relationships with the vendors and teammates that help us solve problems for clients. He’s also responsible for Sales operations and business capture. Outside of work, Andrew enjoys jogging (not running ![]() ) and catching live acts at one of DC’s myriad venues.

) and catching live acts at one of DC’s myriad venues.